- Sales Brochure

- Installation, Operation & Maintenance Manual (IOM)

- Specifications (operating & materials)

- Outline Dimensions

- Parts Details

Application Sales Brochures

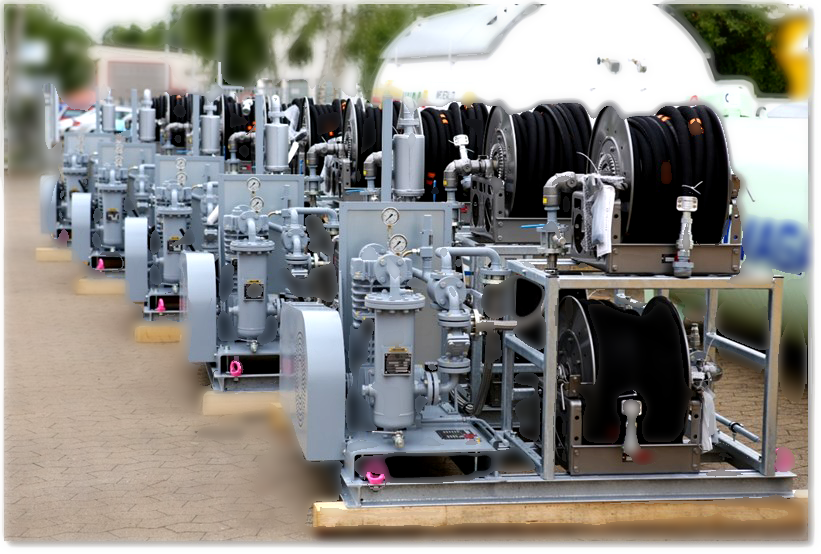

- Vapor Recovery Compressor (VRU)

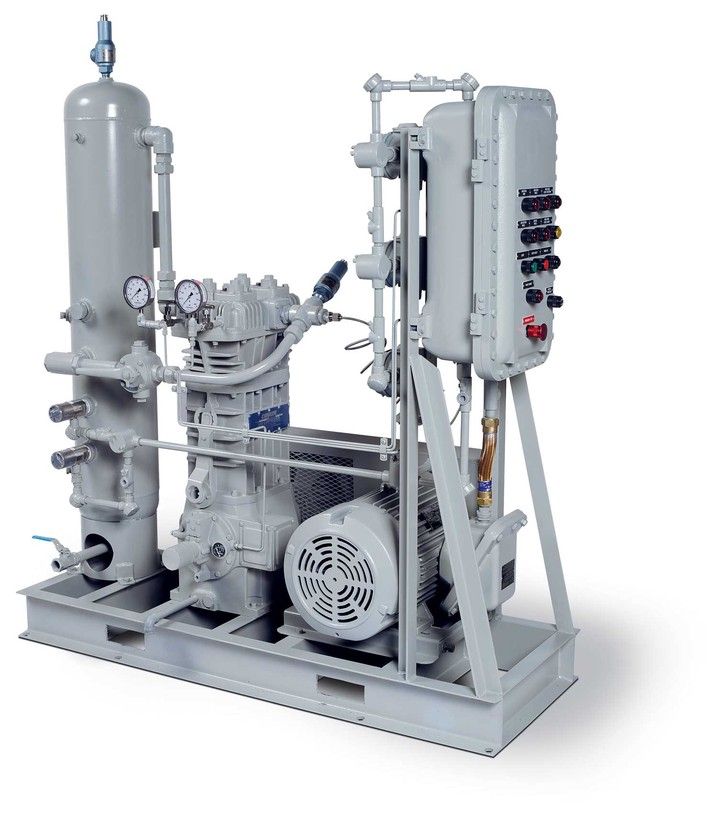

- Custom Engineered Compressor Packages

- Casing Gas, Gas Gathering, and Gas Boosting

D- and T-Style Models (Industrial)

- Sales Brochure

- Corken Important Instructions

- Corken Installation, Operation & Maintenance Manual (IOM)

- Specifications (operating & materials)

- Outline Dimensions

- Models 91, 291, 491 (D- and T-Style)

- Model FD151

Models F191 & FD191

Models FD351, WFD351, D391, WD391, FD391, WFD391, T391 & FT391

Model WFD551

Models FD591, WFD591, FT591 & WFT591

Models D691, FD691, T691 & FT691

Models D791, D891, T791 & T891

Parts Details - Model 91 (D- and T-Style)

Model FD151

Models 191 & 291 (D- and T-Style)

Models FD351 and WFD351

Models FD391, WFD391, and WT391

Models 491 and 491-3 (D- and T-Style)

Model WFD551

Model 590 (D- and T-Style)

Model 591 (D- and T-Style)

Models WFD691 and WFD691-4

Models D691, D691-4, T691, and T691-4

Models D791, D891, T791 and T891

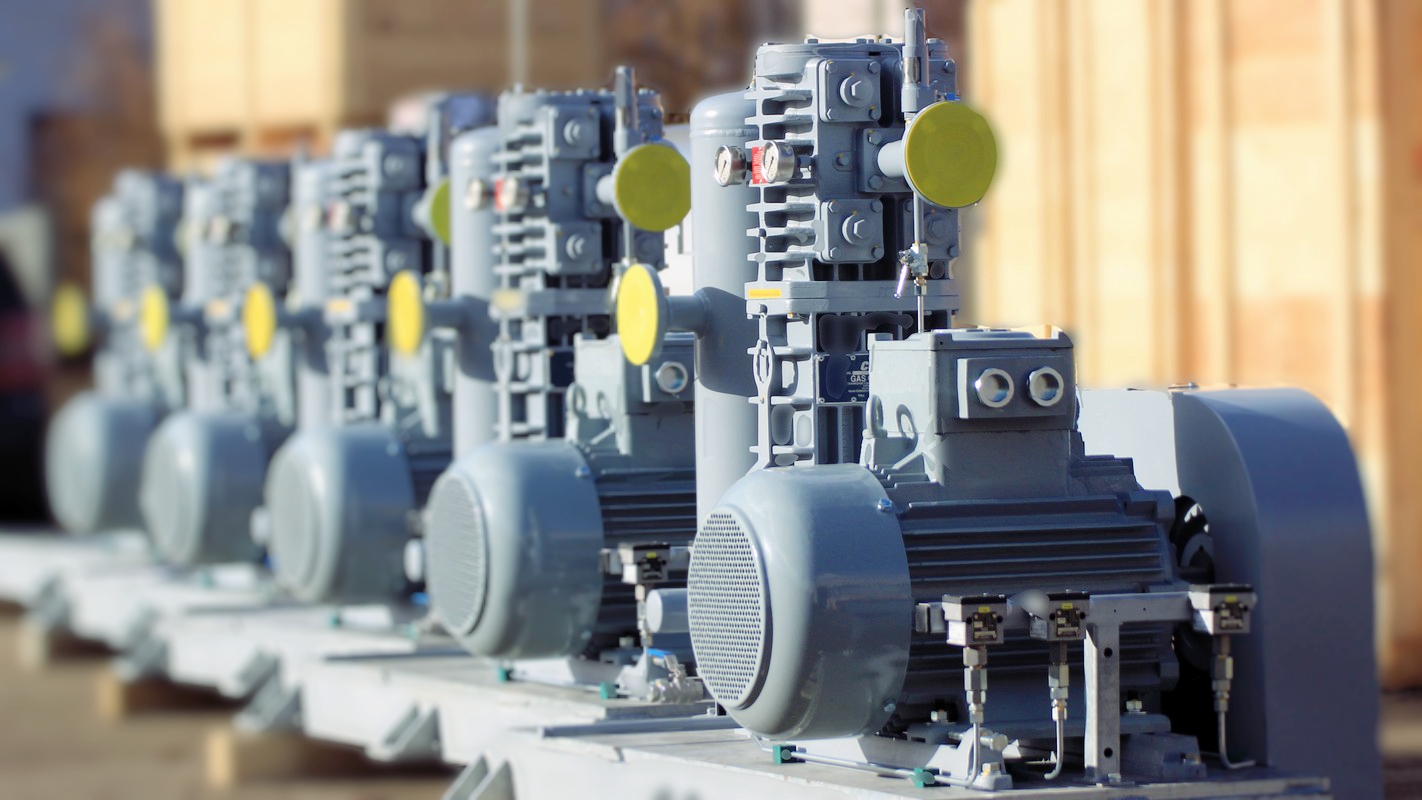

Compressors and compressor aggregates

GeneralCompressors – selection based on gas

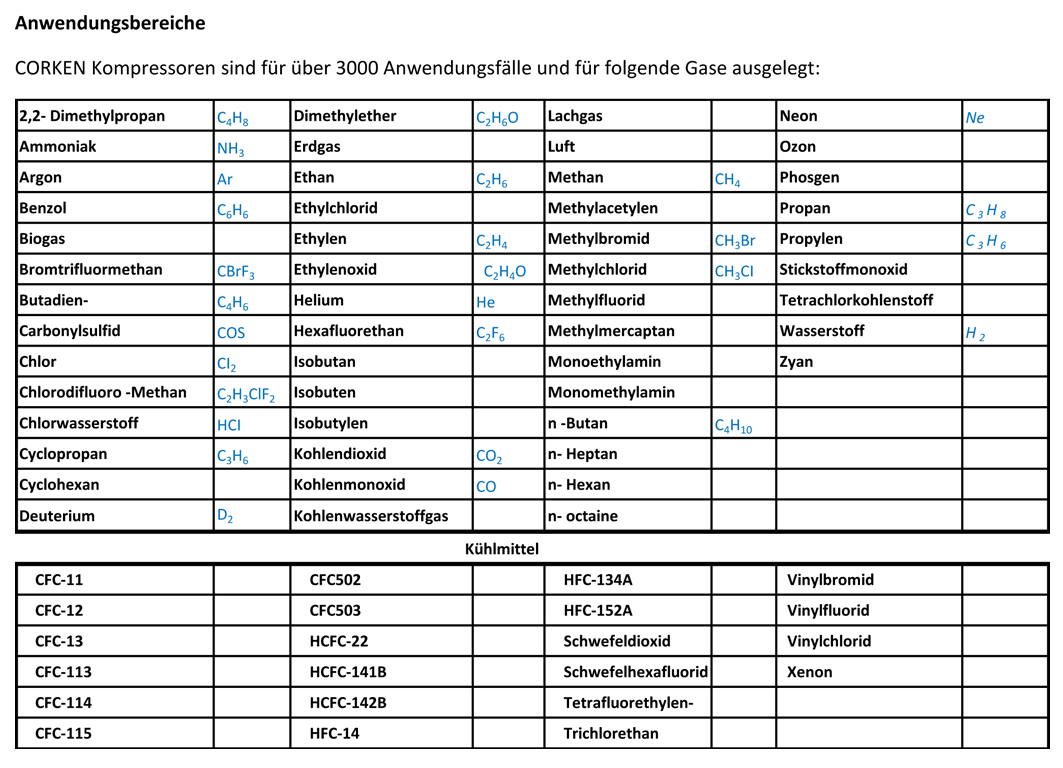

Corkens oil-free condensing compressors are specially designed for industrial applications to cover a wide field of applications for gases. CORKEN compressors are designed for over 3000 use cases and for following gases:

Special solution and further media: contact us – our engineering service enables a quick and effective elaboration of individual projects. To do this, please use our questionnaire and get in touch with us/ contact us at:

Sealing Systems

Explanation of the various seals / sealing chambers

PLAIN-STYLE COMPRESSORS

are simply sealed standard reciprocating compressors (HG601 and HG602) have an oil scraper ring and a sealing unit and are not oil free. These standard reciprocating compressors are typically used in areas where non-corrosive and non-toxic gases are compressed and leakage protection is not of the highest priority. Examples of the fields of application are oil fields with natural gas production and some air pressure areas.

Here is a description of the Plain-Style sealing system

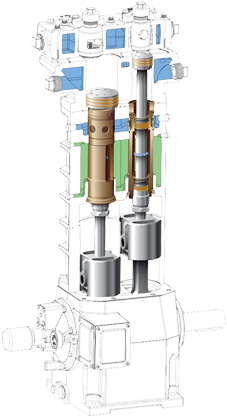

D-STYLE COMPRESSORS

are double sealed compressors and have 2 V-ring sets per piston rod and a sealing chamber. The lower seal has an adjustable seal screw to increase ease of maintenance and thus to ensure a higher tightness. With the exception of models D 791 and D 891, all our D-Style compressors are designed for oil-free gas compression. Main applications are toxic and corrosive gases where the greatest possible attention is paid to oil-free and leakage is not desirable.

Here is a description of the D-Style sealing system

T-STYLE COMPRESSORS

are oil-free compressors with a triple V-ring seal of the piston rod, so that the medium must overcome two “sealing chambers” before it can leak. This “space” created by two V-ring seals is also called a sealing chamber. T-Style compressors are used wherever both oil-free compression of gases and maximum leakage safety must be guaranteed. The industrial T-Style compressors can be operated with many different gases like poisonous, volatile, corrosive and corrosive gases. Examples include: chlorine gas, vinyl chloride, methyl chloride, sulfur dioxide, hydrogen, helium and many other gases.